Business consultants

Trucks - Forklifts Accidents Consultants: 18

Accident Reconstruction Consultant Kevin Forcier

Kevin Forcier

Crash Reconstruction Specialist

21632 South Street

P.O. Box 131

Venango PA

16440-0131

USA

phone: 814-547-1814

fax: 814-398-4173

Private Commercial Transportation Consultant Peter Sullivan

Peter J. Sullivan

5380 W. 34th St., Ste. 347

Houston TX

77092

USA

phone: 281-734-7222

Design Engineering Consultant David Smith

David Smith

Vice President

111 W. Canyon Crest Road

Alpine UT

84004

USA

phone: 801-763-8484

fax: 801-763-5755

Workplace Safety Compliance Consultant Cory Bruner

Cory W. Bruner

Owner

808 Wade Road

New Braunfels TX

78132

USA

phone: 512-230-4491

Packaging Consultant Randy Phares

Randy Phares

President / CEO

15504 N 169th Ave

Surprise Arizona

85388

USA

phone: 775-443-5529

Failure Analysis Consultant William Guentzler

Dr. William D. Guentzler

61115 Fire Barrel Drive

La Quinta CA

92253-7945

USA

phone: 619-823-9081

Diminished Value Auto Appraisal Consultants Houston Auto Appraisers

Roy Theophilus Bent, Jr

Expert Witness / Personal Property Appraiser

1300 Rollingbrook Dr Suite 406

Baytown TX

77521

USA

phone: 281-424-6466

JP Transportation Safety Consulting

Jon (Paul) Dillard

President and Co-Founder

4000 Eagle Point Corporate Dr.

Birmingham AL

35242

USA

phone: 205-945-8550

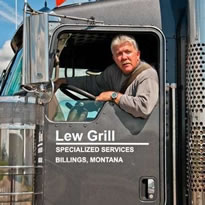

Trucking Consultant Lewis Grill

Lewis Grill

Trucking Expert

3311 Ben Hogan Lane

Billings MT

59106

USA

phone: 406-248-2766

Ergonomics Safety Consultant Jerry Purswell

Dr. J.P Purswell, PhD, PE, CPE

Ergonomic & Safety Consultant

2035 Mulligan Drive

Colorado Springs CO

80920

USA

phone: 719-592-1773

fax: 719-265-6905

Industrial Forensic Engineering Consultants Quality Forensic Engineering LLC

Dr. Brian Pfeifer, PhD, PE

2341 Hansen Court

Tallahassee FL

32301

USA

phone: 850-583-5540

Accident Reconstruction Biomechanics Consultants Quality Forensic Engineering LLC

Dr. Brian Pfeifer, PhD, PE

2341 Hansen Court

Tallahassee FL

32301

USA

phone: 850-583-5540

Forensic Safety Engineering Consultant Kevin Smith

R. Kevin Smith. P.E.

President

1539 Chalone Ct.

Crown Point IN

46307

USA

phone: 219-226-9510 (Office)708-790-1938 (Cell)

fax: 708-755-1580 (Lab Office)

Forensic Engineer Consultant Dr Rasty

Prof. J. Rasty, Ph.D., PE, MBA, CFEI, CFII

Founding President & CEO

2309 19th Street

Lubbock TX

79401

USA

phone: (806) 368-9811

fax: (806) 368-9812

OSHA Safety Construction Consultant Greg Gerganoff

Greg Gerganoff, CSP, Esq.

Certified Safety Professional

Denver, CO

All States USA

phone: 303-330-4616

Featured resources

by Bankole A. Johnson, MD

by Kenneth S. Pope, James N. Butcher, Joyce Seelen

by Walter P. Signorelli, JD

Follow us

Principal, Greg Gerganoff, ASP, CSP, Esq., is an OSHA / MSHA Safety field and compliance expert in the fields of heavy construction, oil and gas, mining, pipeline, power plant outages, light rail construction, public schools, manufacturing, and trenching and excavation.

Principal, Greg Gerganoff, ASP, CSP, Esq., is an OSHA / MSHA Safety field and compliance expert in the fields of heavy construction, oil and gas, mining, pipeline, power plant outages, light rail construction, public schools, manufacturing, and trenching and excavation.