Meticulous Engineering Analysis

- Simple hand calculations.

- Spread sheet analysis.

- Assistance in product development cycles.

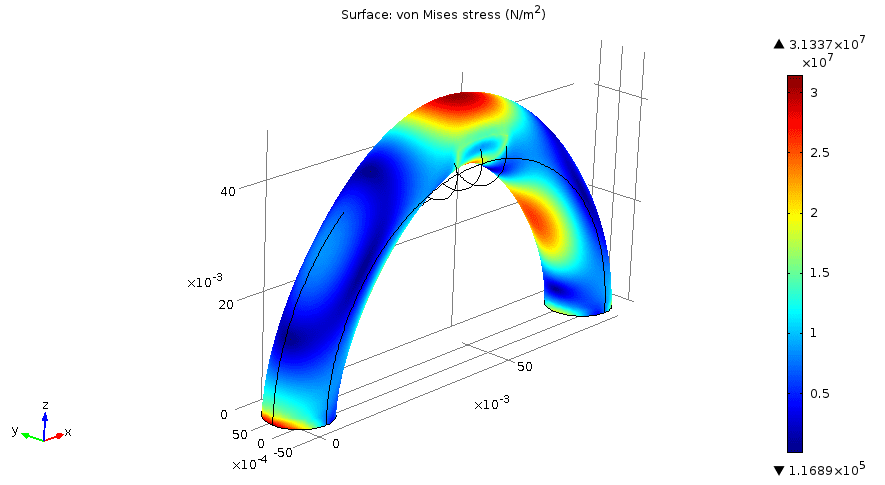

- Structural finite element analysis (FEA).

- Flow and heat transfer analysis via computational fluid dynamics (CFD) or computational heat transfer (CHT).

At Clarksean and Associates we have the experience in analyzing engineering systems via engineering analysis. It may be a single component, it may be several components, or it might be the examination of particular failure modes to assess the safe operation of a system. Whatever your needs, contact us today to determine if we can help you.

Engineering Analysis – Details

- What answer am I looking for?

- Am I designing a brand new part and need to understand the stress levels?

- Am I worried about the maximum temperature the part might see under the most severe conditions?

- How accurate does that answer need to be?

- Will a conservative estimate be adequate? Or will that conservative estimate lead to increased cost and weight?

- Is the component critical to the safe operation of the system? If so, the answer needs to ensure that the part is adequately designed.

- Will cost of the component be impacted by the answer I obtain?

- What level of modeling is even possible for the system?

- Is it possible to model every feature of the design?

- Will the time to complete the analysis beyond the time when the answer is needed?

- Is there an off the shelf software tool to do exactly what you need? Or, will you need to develop your own model to analyze the system?

- How will you verify that the answer you receive is correct?

- If you don’t know what the answer should “look like” then you need to be very cautious to insure the problem was setup and solved properly.

- You may have to run another separate analysis just to insure the answer you have obtained is correct and bounded properly.

- Do you have enough computing horsepower to perform the calculations that you think you need?

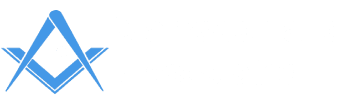

The image below represents the von Mises stress levels for a lifting fixture. In this situation, there was no initial design analysis undertaken to estimate the stress levels in the lifting fixture. The fixture was taken, installed in an inconsistent manner, and there were no lifting instructions as to how best attach chains, etc. to this fixture to ensure it did not fail.

Without this type of information, the user of this device (attached to a slab of concrete) could easily overload the lifting device and cause it to fail. In this situation, that is exactly what happened. Chains were used at very small lifting angles, the device was overloaded, and failed in a ductile fashion. Because this analysis was for a forensic investigation, only enough work needed to be undertaken to show that the lifting device could become overloaded and fail.

But as always you want to do as little work as possible to obtain the quality of the answer desired. This decision may be difficult to make, but experience and a clear knowledge of what you are trying to calculate is the key.

Doing as little work as necessary may sound like you are trying to take shortcuts, but what it is really saying is do the analysis you need for the desired answer, rather than doing the type of analysis you “like” to do. For example, would you want to setup and run a full blown finite element analysis on a bolt just to size the bolt? Or, would a simple hand calculation suffice in order to make the desired determination? The answer is of course dependent on the type of joint, the application, and the bolt being used.

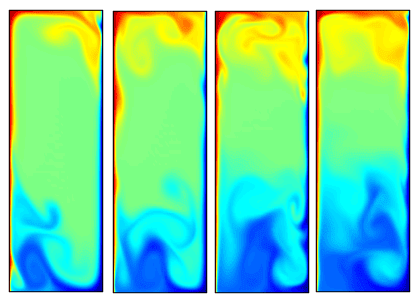

This last image is here to say – yes – hand calculation are often more than enough to obtain the quality of the answer you need. These hand calculations were used to validate a spreadsheet where an energy balance was being calculated to ensure the proper flow rates of fluids were available to meet the flow stream of hot material.