2/3/2014· Failure Analysis

By: Dr. Thomas Read

The root cause of the failure of customer returns of heated automobile rear view mirrors was investigated.

By: Dr. Thomas Read

Tel: (707) 544-2374

Email Dr. Read

As "water hammer" (i.e. liquid impact) has the potential to cause glass bottle failure, Read Consulting LLC created two such failures to study the resulting fracture surface details.

Procedure: Two bottles were filled with warm water to within 3/4" of the top; they were then recapped. While holding the bottle upright, a rubber mallet was used to hit the top cap. After several blows, each bottle failed.

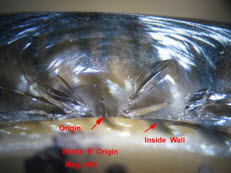

Results: Both failures initiated on the inside wall of the bottle where the base and the body intersect (heel). It is important to note that the bottle's inside wall is fire polished; thus, the glass strength should exceed 5,000 psi. This is confirmed by the very small fracture mirror at each origin. The small mirror indicates that the initiating stress was very high. In addition, the initial fracture is perpendicular to the axis of the bottle. This indicates that these failures are caused by downward forces created by the water. Thus, this is an impact failure; it is very different than a failure caused by high liquid pressure which results in cracks along the bottle axis.

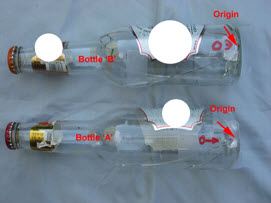

Photographs: Below are photographs of the failed bottles:

Both bottles fractured at the heel (i.e. intersection of the sidewall and the base).

Fracture Origins

Bottle 'A' Fracture Origin

Bottle 'B' Fracture Origin

Dr. Thomas L. Read, CEO of Read Consulting received his PhD. from Stanford University in 1972. He has over 25 years of manufacturing experience in electronics, metallurgy, factory safety, failure analysis, glass fracture, glass failure and bottle failure. As a member of the electronics industry, Dr. Read has earned process patents and has an extensive background in manufacturing techniques. In parallel, he has spent over twenty five years as a consultant to attorneys and engineers in the areas of failure analysis, metallurgy, glass fracture, glass failure, bottle failure, factory safety, manufacturing problems, intellectual property and patent disputes.

©Copyright - All Rights Reserved

DO NOT REPRODUCE WITHOUT WRITTEN PERMISSION BY AUTHOR.

2/3/2014· Failure Analysis

By: Dr. Thomas Read

The root cause of the failure of customer returns of heated automobile rear view mirrors was investigated.

2/17/2023· Failure Analysis

Design Defect Failure Analysis of Water Shut Off Valve

By: Dr. Thomas Read

When this type of valve is open a rubber seal around the valve stem prevents leaking. In this case, the poly acetate stem deteriorated due to the presence of hot chlorinated water This allowed water to leak out. Over time the leak rate increased.

4/1/2011· Failure Analysis

Failure Analysis of a "Exploding" Beer Bottle: Product Defect, Product Liability

By: Dr. Thomas Read

A glass failure expert witness performs a root cause failure analysis on an exploding beer bottle. The object of this root cause failure analysis is to determine the cause of the bottle failure.