2/3/2014· Failure Analysis

By: Dr. Thomas Read

The root cause of the failure of customer returns of heated automobile rear view mirrors was investigated.

By: Dr. Thomas Read

Tel: (707) 544-2374

Email Dr. Read

Read Consulting Failure Analysis Laboratory was engaged to determine the cause of failure of two titanium surgical screws used in corrective back surgery. These were both 6.5 mm diameter, 40mm long screws that were surgically implanted. in a patient, and they subsequently failed.

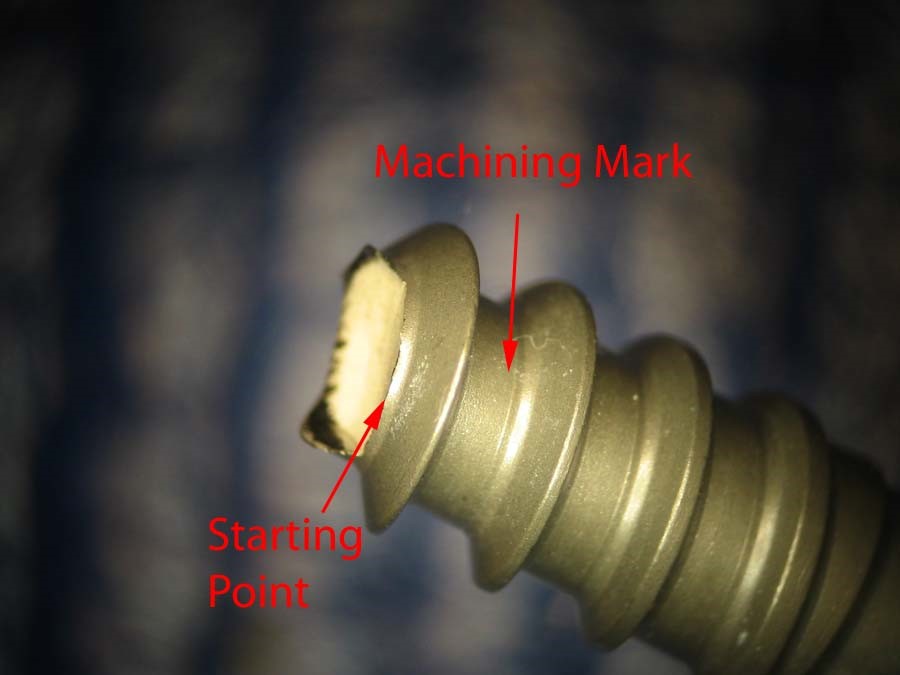

Both screws were made from titanium, aluminum, vanadium alloy. In addition, both failures are attributed to bending fatigue that initiated at the screw’s minor diameter (i.e. at the thread root). One failure initiated at what appears to be a “machining” or “turning” mark on the minor diameter. The other failure initiated at a very similar location, but there is no visible machining mark. In either case, the fatigue cracks started at a stress riser.

Figure #1: Photograph of the two failed screws.

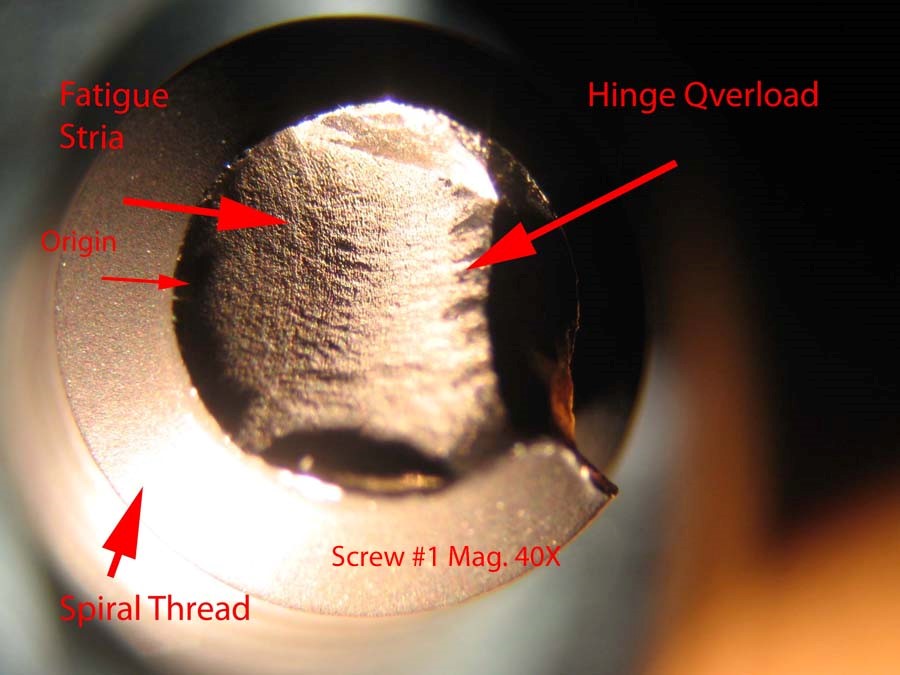

Figure #2: Photomicrograph of the fracture surface on screw #1. This fatigue crack appears to have started at the �root� of the thread.

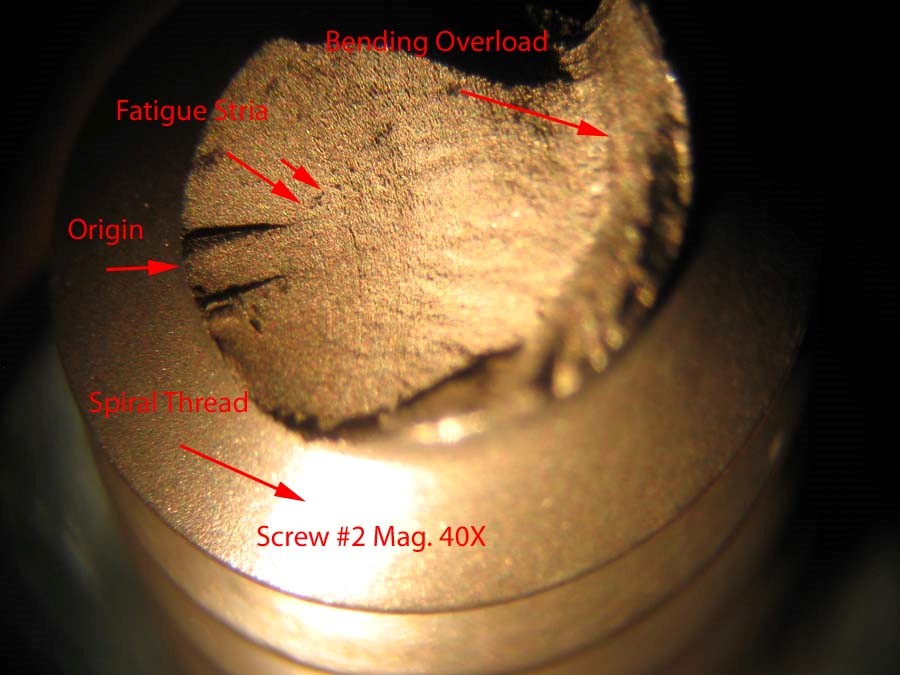

Figure #3: Photomicrograph of the fracture surface on screw #2. This fatigue crack appears to have started at a machining mark in the root of the thread.

Figure #2: Photomicrograph of the fracture surface on screw #1. This fatigue crack appears to have started at the �root� of the thread.

Figure #4: Photomicrograph side view of screw #2. This fatigue crack appears to have started at a machining mark in the "root" of the thread.

Dr. Thomas L. Read, CEO of Read Consulting received his PhD. from Stanford University in 1972. He has over 25 years of manufacturing experience in electronics, metallurgy, factory safety, failure analysis, glass fracture, glass failure and bottle failure. As a member of the electronics industry, Dr. Read has earned process patents and has an extensive background in manufacturing techniques. In parallel, he has spent over twenty five years as a consultant to attorneys and engineers in the areas of failure analysis, metallurgy, glass fracture, glass failure, bottle failure, factory safety, manufacturing problems, intellectual property and patent disputes.

©Copyright - All Rights Reserved

DO NOT REPRODUCE WITHOUT WRITTEN PERMISSION BY AUTHOR.

2/3/2014· Failure Analysis

By: Dr. Thomas Read

The root cause of the failure of customer returns of heated automobile rear view mirrors was investigated.

11/8/2011· Failure Analysis

Root Cause Failure Analysis of Tempered Glass Door

By: Dr. Thomas Read

Glass Failure Analysis Expert Witness performs a failure analysis of a several tempered glass doors that had "spontaneously" failed at a construction site. The objective of this glass failure analysis is to determine the cause of failure and make recommendations to the contractor.

4/12/2021· Failure Analysis

Glass Failure Analysis: Glass Oven Dish Failure

By: Dr. Thomas Read

The annealed borosilicate glass pie plate failed as a result of “thermal shock”. There were multiple origins for the failure, and these all initiated at damage sites on the bottom of the Pyrex baking dish. It appears that the bottom of the pie plate was convex. Thus, setting the dish down and moving it on hard (abrasive) surfaces such as tile or granite counters created bottom “rim” damage.