1. INTRODUCTION

A critical path method (CPM) schedule or programme is a dynamic planning tool that engineering and construction industry planners and schedulers commonly use to manage, coordinate, and forecast work activities based on activity durations and logic. It is paramount that a CPM schedule accurately calculate forecasted dates for work activities contained in the schedule. Planners and schedulers commonly apply date constraints to work activities or milestone activities in a CPM schedule to represent contractually required completion dates for either intermediate milestone activities or an overall project finish date.1

A planner or scheduler may also apply date constraints to represent crucial need dates, such as the completion of issued-for-construction drawings, shipment of long-lead equipment, customs clearance, delivery of equipment and materials to a project site, start of field installation, completion of foundations, erection of structural steel, fabrication of process pipe, mounting of instruments, area or system turnover, mechanical completion, or ready-for-startup tasks. During project execution, this insertion of date constraints allows planners and schedulers to gauge schedule progress relative to the date-constrained work activities.

Commercially available critical path method scheduling programs, such as Oracle Primavera (P6), provide nine constraint types to use in a schedule, as listed in Table 1-1 below.

Table 1-1: Listing of Available P6 Constraint Types

Item No. |

Constraint Type |

Constraint Category |

1 |

Start-On Constraint |

Soft Constraint |

2 |

Start-On-Or-After Constraint |

Soft Constraint |

3 |

Start-On-Or-Before Constraint |

Soft Constraint |

4 |

Finish-On Constraint |

Soft Constraint |

5 |

Finish-On-Or-After Constraint |

Soft Constraint |

6 |

Finish-On-Or-Before Constraint |

Soft Constraint |

7 |

As-Late-As-Possible (“ALAP”) Constraint |

Soft Constraint |

8 |

Mandatory Start Constraint |

Hard Constraint |

9 |

Mandatory Finish Constraint |

Hard Constraint |

As identified above, most of the constraint types, i.e., item numbers 1 through 7, are commonly categorized as soft constraints that allow schedule logic to be maintained and prioritized over the constraint date. In contrast, for item numbers 8 and 9, mandatory constraint types are commonly categorized as hard constraints. Hard constraints are unique in that the hard constraint date takes priority over schedule logic. Consequently, if a hard date constraint takes priority over the planned schedule logic flow, then the determination of true critical and near-critical paths may not be properly calculated.

Therefore, it is not surprising that the use of mandatory start and finish constraints is discouraged in the construction scheduling industry. Although planners and schedulers are not barred from using mandatory start and finish constraints, these constraints may artificially change the critical path, make proper examination of float values difficult, interrupt a continuous path through work activities, and cause differing float values from one activity to the next activity within a given logic chain. For these reasons, the use of mandatory constraints can be problematic, especially when a planner or scheduler is required to report the real driving critical path as well as accurately forecasted completion dates to stakeholders, or when parties are trying to accurately quantify or prove schedule delay.

The purpose of this article is to promote awareness and discussion regarding problems created when using mandatory constraints as well as to recommend more reasonable constraint type alternatives.

2. WHAT ARE MANDATORY CONSTRAINTS?

In CPM scheduling, mandatory start and finish constraints are generally defined as imposed date restrictions applied to either the start date or finish date of a task activity or milestone activity. The key feature, as well as the most problematic, is that mandatory start and finish constraints override existing CPM schedule logic and force the early dates and/or late dates to equal the mandatory constraint date. Mandatory constraints can cause differing float values to predecessor or successor activities within a logic chain, thus causing confusion when trying to determine the true critical path.

Even if predecessor activity forecasted dates are later than an imposed mandatory constraint date, the predecessor logic links are ignored by the mandatory constraint. Intuitively, it does not make logical sense to start work before the preceding work is finished based on the planned logic. It becomes more problematic if a schedule contains thousands of work activities and has numerous mandatory constraints throughout the schedule. A schedule with even very few mandatory constraints applied to task or milestone activities can create confusion regarding the critical path and/or near-critical paths.

Mandatory constraints could create conditions that can cause work activities within a driving critical path chain to have negative, positive, and/or zero total float values. Some stakeholders are unfamiliar with how mandatory constraints can calculate forecasted dates and total float values.

Differing float values on driving critical path activities could cause such stakeholders to wrongly conclude that an activity is behind or ahead of schedule.

Therefore, many scheduling practitioners along with several recognized industry publications discourage the use of mandatory constraints. For instance, AACE International’s Recommended Practice (RP) 49R-06, titled “Identifying the Critical Path,” states:

This type of constraint forces a start or finish date to be observed even if CPM logic otherwise forbids the occurrence. This RP strongly recommends against the use of mandatory constraints as they lead to illogical results where activities are scheduled to occur even if preceding work is incomplete.2

Similarly, the U.S. Government Accountability Office (GAO) Schedule Assessment Guide: Best Practices for Project Schedules, discourages the use of mandatory constraints. The GAO uses the acronym MSON to define a Mandatory Start constraint and the acronym MFON for a Mandatory Finish constraint. The GAO states:

Because MSON and MFON constraints prevent activities not only from slipping but also from accelerating, their use is discouraged. They should never appear in the schedule baseline. If not properly justified in working schedules, they must be immediately questioned.3

3. PROBLEMS WITH MANDATORY START CONSTRAINTS

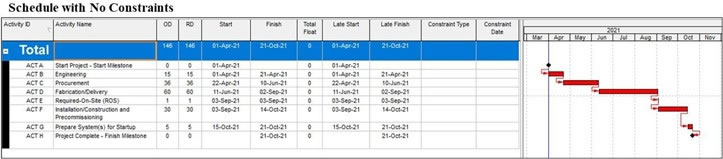

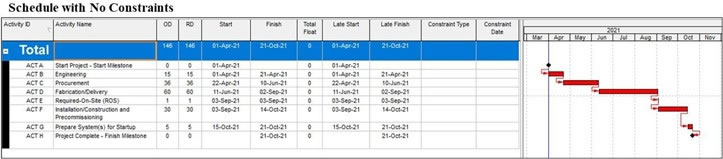

To illustrate the problem created when using mandatory start constraints, Figure 3-1 below presents a simple P6 bar chart schedule that summarizes the as-planned schedule of a group of task activities and milestones. The schedule is free of constraints and has a data date of 1 April 2021. The critical path starts with Activity ID ACT A, “Start Project – Start Milestone.” Based on the durations and logic of successor activities, the critical path traces from ACT A through the project completion activity shown by ACT H, “Project Complete – Finish Milestone.” ACT H has a forecasted overall finish date of 21 October 2021. The early dates and late dates for all activities are the same with float equal to zero. Thus, the project is planned to finish on 21 October 2021.

Figure 3-1: Simple As-Planned P6 Bar Chart

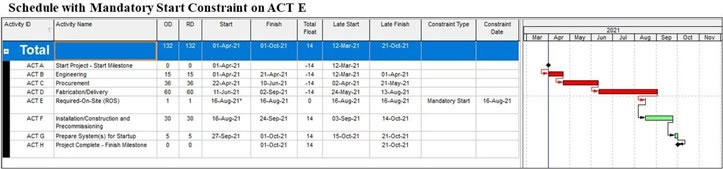

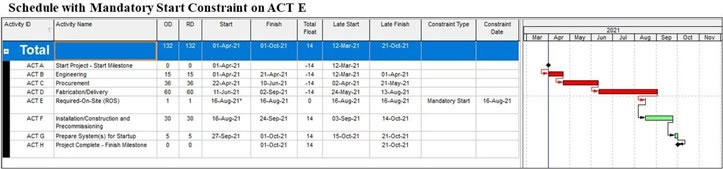

In Figure 3-2 below, a 16 August 2021 mandatory start constraint was applied to ACT E, “Required-On-Site (ROS).” The imposed mandatory start constraint forced ACT E’s early and late dates to be 16 August 2021. When compared to the 3 September 2021 original forecasted start and finish date, ACT E’s 16 August 2021 mandatory start constraint date is 14 workdays or 18 calendar days earlier than 3 September 2021, and ACT E’s total float value is artificially forced to be zero workdays.

Figure 3-2: Simple As-Planned Bar Chart with a Mandatory Start Constraint

As shown above, ACT E’s immediate predecessor, ACT D, “Fabrication/Delivery,” has a calculated early finish date of 2 September 2021. Based on early dates, it is reasonable to conclude that ACT E cannot start any earlier than 3 September 2021, which is the next day after ACT D’s early finish date of 2 September 2021. Table 3-1 highlights the interrupted logic problem between ACT D and ACT E.

Table 3-1: Problem Created between ACT D and ACT E Due to a Mandatory Start Constraint Applied to ACT E

Activity ID |

Description |

Logic Link |

OD in Workdays |

Early Start Date |

Early Finish Date |

Total Float in Workdays |

Applied Constraint |

ACT D |

Fabrication/Delivery |

|

60 |

11JUN21 |

02SEP21 |

-14 |

|

|

Logic Link between ACT D and ACT E |

Finish-to-Start with zero-day lag (i.e., FS 0) |

|

|

|

|

|

ACT E |

Required-On-Site (ROS) |

|

1 |

16AUG21 |

16AUG21 |

0 |

Mandatory Start of 16AUG21 |

The mandatory start constraint applied to ACT E overrides the predecessor finish-to-start logic link from the ACT D fabrication and delivery work. The mandatory start constraint permits ACT E to start on 16 August 2021, even though the delivery activity will not occur until 2 September 2021. How is it possible to install equipment when the equipment is forecasted to be delivered 14 workdays later? This does not make logical sense.

In Figure 3-2 above, the mandatory start constraint applied to ACT E also affects the total float values of ACT E’s predecessor logic chain. The late finish date of the fabrication and delivery predecessor ACT D is calculated to be 13 August 2021. When comparing ACT D’s forecasted 2 September 2021 early finish date to its 13 August 2021 forecasted late finish date, ACT D’s total float value is negative 14 workdays. In fact, ACT E’s entire predecessor chain shows negative 14 workdays of total float directly caused by the 16 August 2021 mandatory start constraint that was applied to ACT E.

In contrast, the forecasted dates and float values to ACT E’s successor logic chain are affected differently. For example, the early start date of the immediate successor ACT F, “Installation/ Construction and Precommissioning,” is forecasted to start on 16 August 2021, which is the same day as ACT E’s 16 August 2021 mandatory start constraint date.4 ACT F’s forecasted 16 August 2021 early start date and 24 September 2021 early finish date are 14 workdays earlier than its original 3 September 2021 late start date and 14 October 2021 late finish date as shown in Figure 3-1. The difference in early and late dates for ACT F shows available float of 14 workdays. Table 3-2 highlights the positive total float generated between ACT E and ACT F.

Conintue Reading....Download PDF with footnotes, figures, tables, and references.